Hotline

+86-0519-86579357

Welcome to the official website of Changzhou Zhuangyuan Electrical Manufacturing Co., Ltd!

The bearing heater (bearing induction heater) uses the principle of power frequency induction eddy current heating to conduct rapid induction heating for the bearing. The whole body of the bearing inner sleeve is heated evenly and expanded outward in equal amount. The expanded bearing can be assembled with the shaft interference heat sleeve smoothly. This installation method will not damage the bearing and spindle.

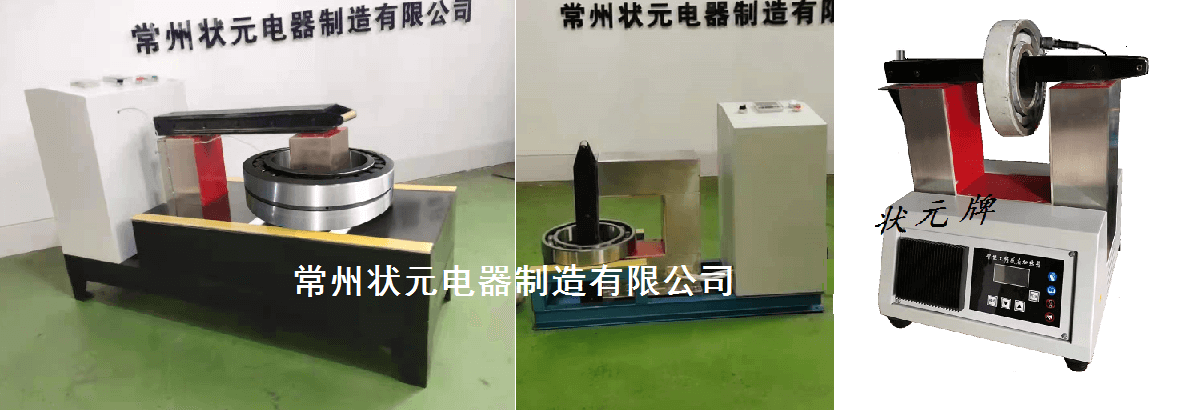

1、 Zhuangyuan bearing heater

The bearing heater adopts the principle of eddy current induction heating. There are three groups of copper coil windings in Zhuangyuan brand bearing heating equipment, including ultra thick pure copper coil. Domestic manufacturers engaged in bearing induction heating equipment for a long time, used for bearing heating ten years will not break, super long service life, a large number of users 13 ~ 15 years ago to buy, is still in use!

2、 Structure composition

1. The bearing heater is composed of power frequency induction heating host, power distribution control system, matching yoke and base, which is mechatronic.

2. The inner part is composed of high quality flat copper double glass fiber coil winding and high magnetic conductivity silicon steel core. The main engine shell is made of 304 high quality stainless steel.

3. All electrical components are of long life, good reputation and general brand in the market, which is convenient for replacement and maintenance.

4. Considering that the workers operate with thick heat insulation gloves, the button switch adopts large raised machine button, which is convenient to open.

5. The frame is made of steel frame, which is durable and durable. The styles are trolley type, mobile type, fixed type and table top.

3、 Product advantages

Efficient "Champion" brand heater, high thermal efficiency, heating speed, improve work efficiency and assembly speed.

Convenient It can be used immediately without preheating. It will automatically jump off when it reaches the set time, which is convenient and fast.

Reliable Heating is uniform and expansion is equal. It is produced by mechanical manufacturing method and has a long service life.

Security Built in overheat protection system, can be used continuously for a long time, suitable for assembly line operation, reliable operation.

Environment protection Low energy consumption and zero emission are conducive to the improvement of the environment and the health of workers. Demagnetization, automatic demagnetization, after heating the residual magnetic bearing is less than 3 Gauss, in line with the national standard.

| Bearing heater | Model | CY(KVA) | Voltage(V) | Electric current(A) | Heating bearing range(mm) | ||

| Internal diameter | Maximum outer diameter | Maximum width | |||||

| ZY-280 | 2.2 | 220 | 10 | 25-100 | 280 | 100 | |

| ZY-450 | 6 | 380 | 15.8 | 60-300 | 450 | 150 | |

| ZY-550 | 9 | 380 | 23.7 | 80-400 | 550 | 205 | |

| ZY-650 | 13 | 380 | 34.2 | 100-500 | 650 | 240 | |

| Note: the table is ZY series bearing heater commonly used models, other series please consult our manufacturers, beyond the size range, the group according to the bearing size customized non-standard heating equipment, telephone Email contact :czzydq@163.com | |||||||

The bearing remover is used for the heating and disassembly of the bearing inner sleeve, also called the bearing inner sleeve remover and the inner ring disassembly and assembly machine.,The picture above shows the disassembly and assembly site of roll bearing in steel plant,Using a bearing heater.  Professional production of bearing heating machine, bearing heating assembly machine, bearing hot sleeve machine nearly 20 years, the number one brand to build into the industry brand, quality model

Professional production of bearing heating machine, bearing heating assembly machine, bearing hot sleeve machine nearly 20 years, the number one brand to build into the industry brand, quality model

Energy saving and high efficiency

20 years of experience, continuous technological innovation

Heat evenly and expand in equal amount

Master core technology and purchase famous brand accessories

Easy to operate for long life

Strict management, professional production team to

Quick response of after-sales service

Let you reduce investment and run without worry

24-hour hotline:+8613813682742

Common induction heater questions Common induction heater questions

Company news Industry news News Center

Committed to equipment development and productionConsult immediately for product quotation

Hotline:+86-0519-86579357